What started as simply running meters in the abandoned hog shed more than 15 years ago evolved into consistent status as a Precision Planting Premier Dealer. We pride ourselves on not only knowing about Precision Planting technologies, but also running those same parts in our own equipment so we can support you best in the field.

Learn more about our Johnson Precision here, and don’t hesitate to contact us today with your questions at (815) 878-2419.

AirForce takes information from SeedSense and uses air to automatically increase or decrease the weight on the row unit. So you can ensure proper planting depth and avoid root-stunting sidewall compaction, for all planter types.

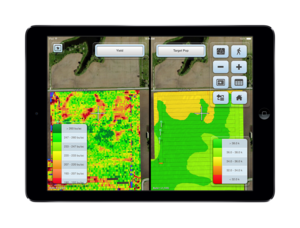

SeedSense is the monitor that makes changes that make you money. It gives you everything you need to know about your planter’s performance. Maximize your speed without compromising ride. Reduce compaction and control depth. And most of all, you can see everything you need to know about your planter, in real time.

With YieldSense, you can make better decisions with more accurate yield data that you can trust, wirelessly with FieldView Plus. Multiple machines syncing harvest data as you’re in the fi eld just makes sense. Furthermore, the RemoteView feature means you can see your combines no matter where you are.

The Precision Meter improves your planter’s performance in the meter by holding one seed at a time, then releasing it. See fewer skips and doubles and as a result, higher yield.

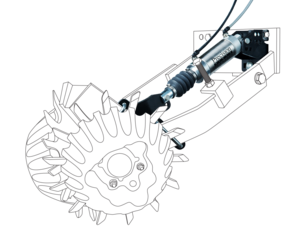

The air cylinder lets you set and adjust your row cleaners’ down pressure from the cab, so you can continuously adjust to changing field conditions. See more uniform germination and higher plant counts. Now row cleaning is easy!

Optical sensors don’t know the difference between dust and seeds. WaveVision does, so you get accurate data to improve planting and yield. Eliminate the errors of optical sensors, and get the population you want.

With RowFlow, growers can precisely execute variable rate prescriptions, avoid overpopulation and minimize inputs, and even add liquid fertilizer control. It gets the right seeding rate in the right place, so you can lower costs while raising yields.

The maintenance parts of the planter are gone. No more lubing chains, sprockets, and drives, and no more worrying about hydraulics. You can clean up your planter with a drive on every row. Conventional drive systems plant too many seeds on the inside of a curve and too few on the outside. vDrive maintains the prescribed population on each row at every spot around a curve, so your yield potential stays high.

You no longer have to compromise when choosing the best hybrid for your fields. With vSet Select, you can pick the right hybrid for the right spot in your field; backed by industry-leading vSet and vDrive technology, it automatically switches so the right seed goes in the right spot.

Make the most of your planting window and maximize productivity with SpeedTube, the seed tube with speed. The flighted belt makes the difference so you can go double the speed while maintaining picket-fence stand perfection.

DeltaForce automatically controls weight on each individual row, creating the perfect seed environment. So you avoid root compaction and achieve higher yields. With an average 11.5 bushel* per acre advantage over fixed management, you can see why taking control pays off .

AirForce takes information from SeedSense and uses air to automatically increase or decrease the weight on the row unit. So you can ensure proper planting depth and avoid root-stunting sidewall compaction, for all planter types.

With BullsEye, you get the most direct path to the seed trench with a smooth interior and recessed sensor eye to eliminate any interference for the seed. You’ll get better spacing, longer seed tube life with tungsten carbide tips — all easily and quickly.